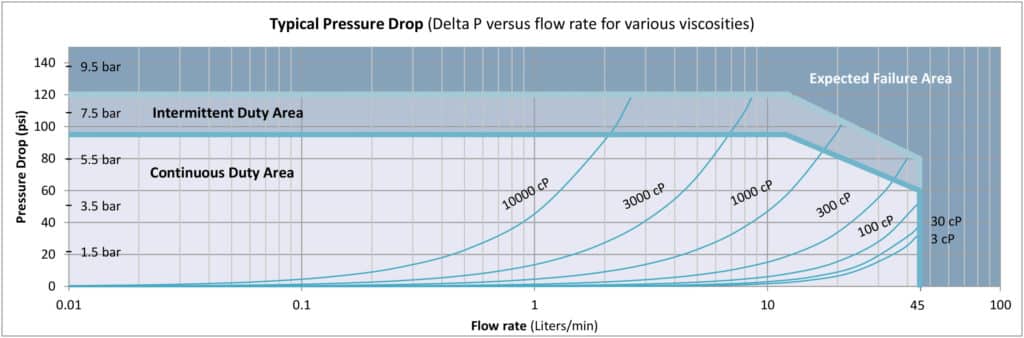

| Flow | 25 cc/min to 45 liters/min; 0.006 to 11.88 gpm |

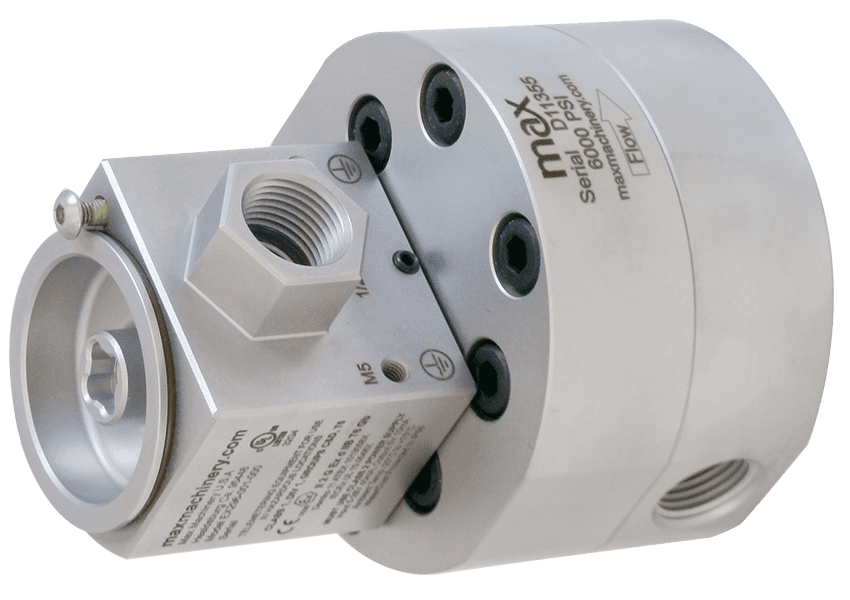

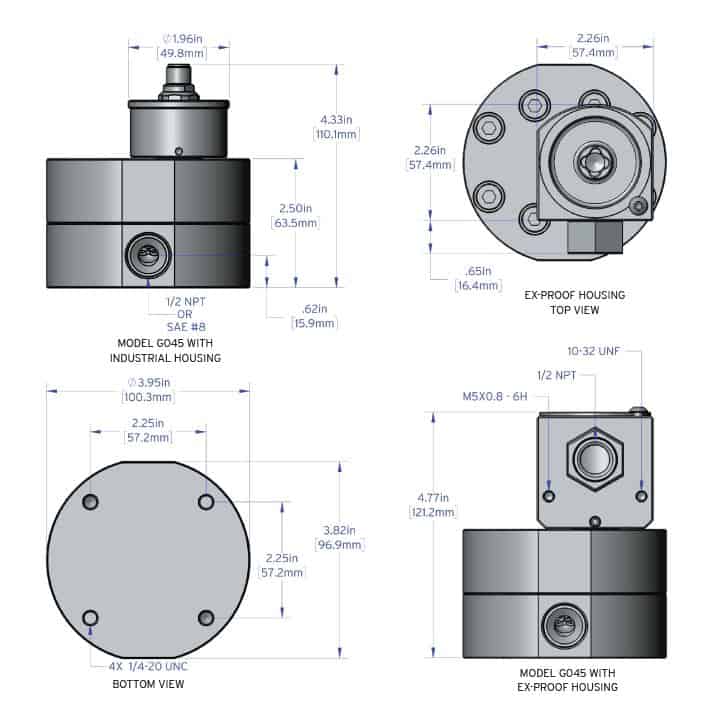

| Port Size | 1/2″ NPT or #8 SAE or Manifold Mount |

| Accuracy | (at 30 cP): ± 0.3% of reading over a 100:1 range |

| Pressure | 6000 psi (414 bar) maximum |

| K-Factor | 70,000 pulses/L |

| Fluids | Most non aqueous, hydrocarbon based liquids |

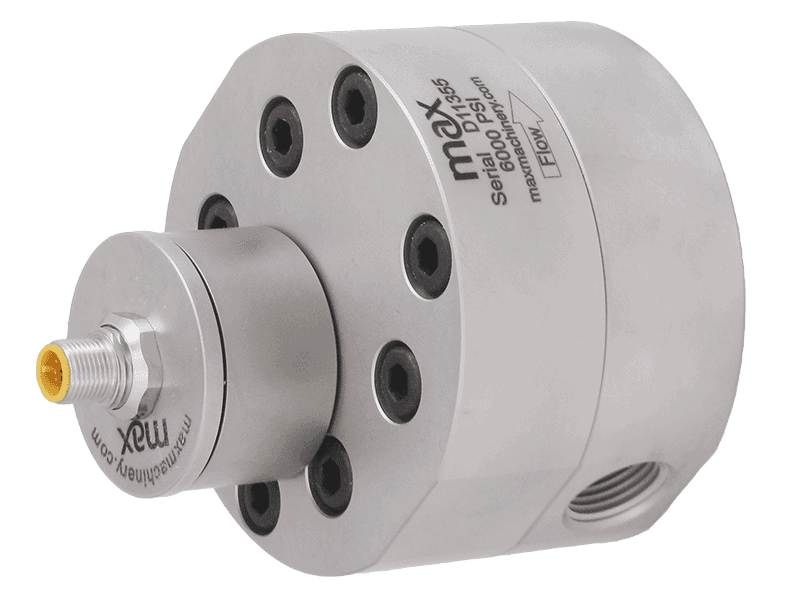

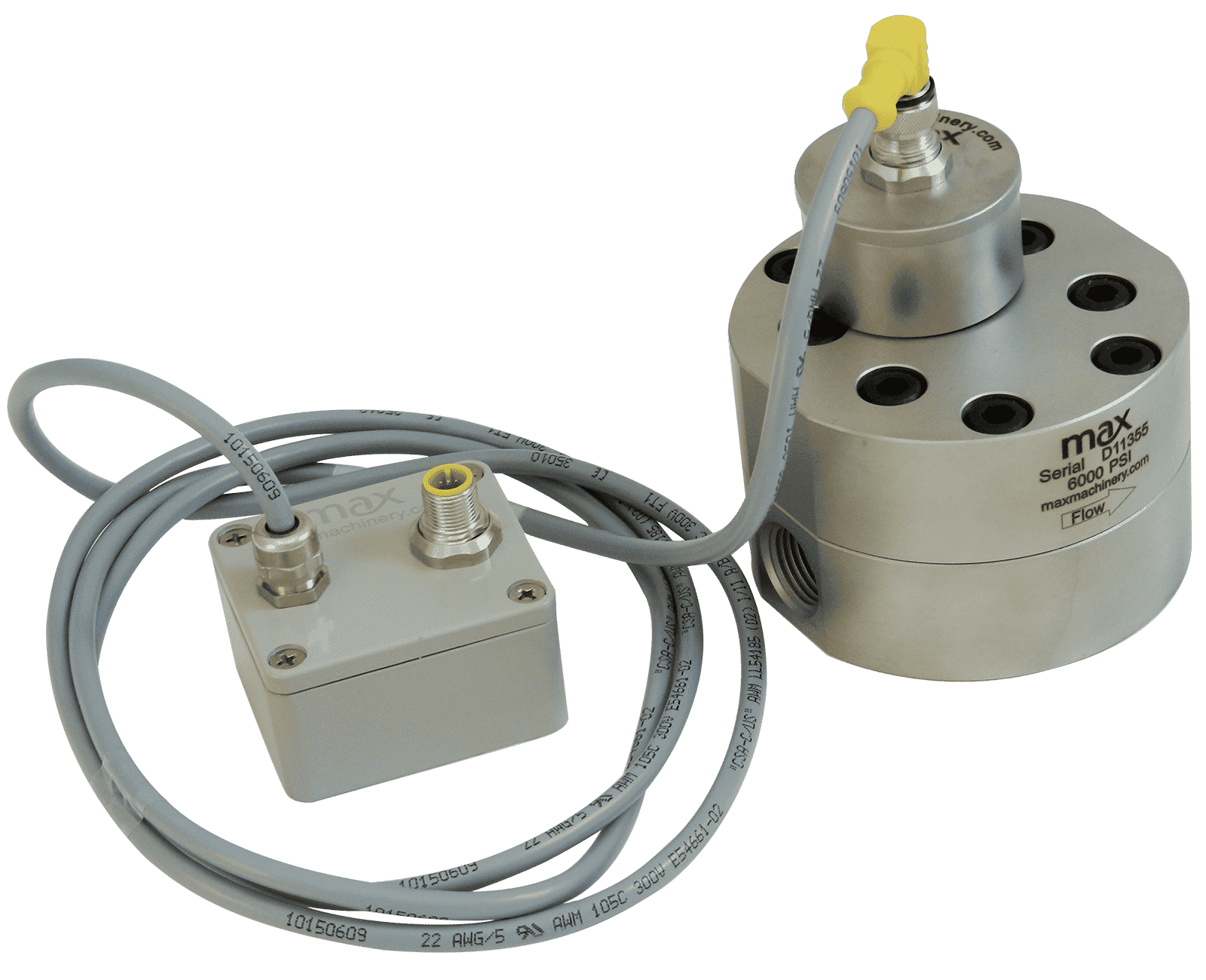

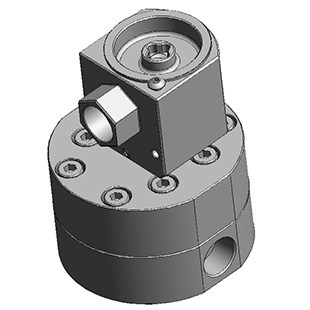

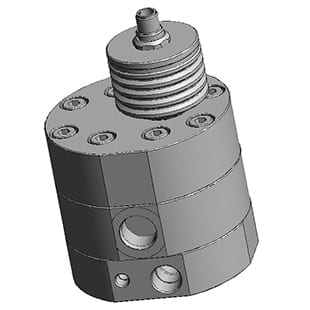

G045 Gear Flow Meter

If you value your flow, find value in the data from a Max Gear Meter. From heavy duty hydraulics to adhesive dispensing, Max Gear Meters provide more data per liter of fluid to give you more control of your flow.

Choose from frequency or analog transmitter options. High temperature models up to 225°C available. CE Certified, Ex-proof version available with ATEX/IECEx and UL/cUL certifications.

Specifications

MECHANICAL

|

Filtration

|

30 Micron recommended

|

|

Weight

|

3.7 kg (8.1 lbs)

|

MATERIALS OF CONSTRUCTION

|

External

|

Stainless steel, type 303; Fluoropolymer coated bolts;

MoS2 lubricant

|

|

Wetted

|

Stainless steel, type 303, 440C, 17-4;

Nickel plated SmCo magnet

|

|

O-Rings

|

Standard: Viton®

Optional: Teflon®, Perfluoroelastomer |

TRANSMITTER VARIATIONS

|

Signal Type

|

Output

|

Resolution (K-Factor)

|

Std. Temp†

|

High Temp†

|

Ultra Temp

|

|---|---|---|---|---|---|

|

Frequency

|

5 VDC square wave (current sinking available)

|

70,000 pulses/L

|

90°C

|

155°C

|

225°C

|

|

Frequency

|

5 VDC quadrature (2-phase)

|

35,000 pulses/L/phase

|

90°C

|

155°C

|

225°C

|

|

Analog

|

0-10 VDC

|

Uni or Bi-directional

|

90°C

|

155°C

|

225°C

|

|

Analog

|

4-20 mA

|

Uni or Bi-directional

|

90°C

|

155°C

|

225°C

|

|

Compliance:

|

CE Certified, Ex-proof version available with ATEX/IECEx II 2 G Ex db IIB Tx Gb as well as UL, cUL certification for Class 1, Division 1, Groups C and D, Tx.†Maximum temperature rating for ATEX certified transmitters is 75°C Std. Temp and 130°C High Temp.

|

||||

Applications

-

Hydraulic Valve, Pump, and Cylinder Testing

Testing of hydraulic valves, pumps and cylinders covers a wide range of flows. From full flow…

-

Chemical Additives Injection Measurement

Chemical additives injection is a broad description for a varied set of applications that require a…

-

Hot Melt Adhesive Dispensing Applications Measured to a Fraction of a Gram

Quality and performance can change with a small amount of material in thermoplastic and reactive hotmelt…

-

Precise Polyurethane Ratio Control

Polyol and isocyanate blending applications for cast elastomers, and rigid or flexible foam applications such as…

-

Aviation Hydraulic Testing

Testing of hydraulic fluid throughout an aircraft’s hydraulic pumps, motors, cylinders and actuators to operate wheel…

Downloads

| GEAR FLOW METERS | MANUAL | ANALOG SPEC SHEET | FREQUENCY SPEC SHEET | PN SELECTOR | CALIBRATION EXAMPLE |

|---|---|---|---|---|---|

|

G045 Gear Flow Meter

|

Drawings / Charts

Related STEP Files

-

Gear Meter STEP Files

G045-INDUSTRIAL-225C-TEMP-RATING-WITH-HEAT-TRACE- STEP File

Free Download Add to cart